With a projection of 997 million tons produced in 2029 (OECD-FAO), milk is considered an important source of protein for humans worldwide. Therefore, it is essential that the entire dairy production chain is safeguarded by ensuring milk quality from the start. However, unknown to many consumers, mycotoxin-contaminated feed fed to lactating dairy cows can introduce toxic metabolites into the milk and consequently present a risk to human health.

Food safety is a broad concept with an especially important part involving tracking the presence and amount of toxic metabolites (mycotoxins) originating from molds and fungi. This is essential because some mycotoxins can be transferred through the animal and into our food. Though food safety involves the entire production process, it starts with farmers providing high-quality feed to the animals.

Feed directly influences dairy cattle performance. For high-quality milk, cows require feed that is of high-quality not only nutritionally but also in terms of safety. The greatest risks to feed safety are the often invisible, tasteless, and heat-stable mycotoxins. It is of utmost importance that these toxins do not impair animal health and performance, let alone affect milk safety. In the case of mycotoxins transferring from feed, food safety starts with the prevention of mycotoxins from entering the animal and continues by preventing their metabolites from being transferred to milk.

Monitoring molds

In recent years—with improved sensitivity of testing methods and the impact of climate change—it is estimated that 60–80% of samples taken have mycotoxins above the detectable level (Eskola et al., 2019). The effects of mycotoxins include lost crops, reduced livestock productivity, as well as increased costs for testing and regulatory programs.

Molds can produce mycotoxins both pre-harvest (Figure 1), post-harvest during storage (Figure 2), and even in the total mixed ration (TMR) at feed out. No matter the location, mycotoxins are only produced by certain molds and under certain conditions if:

- There is readily available starch from grains

- There is a stressor(s) to the molds favorable environment

- Too warm or cold

- Too dry or moist

The conditions most suitable for mold growth and mycotoxin production are different per type of mold (Table 1). In dairy cattle, Aspergillus and Fusarium molds produce the most impactful mycotoxins to dairy.

Table 1: Sources and conditions for mycotoxin formation (Osweiler and Ensley, 2012; Negash, 2018)

Mycotoxins | Mold source | Grains affected | Optimal temperature, humidty, and moisture | Favorable conditions |

| Aflatoxin (B1, B2, G1, G2) | Aspergillus flavus Aspergillus parasiticus | Corn, sorghum, cottonseed, and peanuts | 12–35° C 80–85% relative humidity 3–18% moisture content | Damaged grain, constant high temperatures, and humidity |

| Vomitoxin (DON) | Fusarium graminearum | Corn, wheat, barley, sorghum, rye, and others | 26–28° C 88% relative humidity 22% moisture content | Alternating warm and cool temperatures during the growing season with high humidity |

| Zearalenone | Fusarium graminearum | Corn, wheat, barley, and sorghum | 7–21 °C 24% moisture content | Alternating warm and cool temperatures during the growing season |

| Fuminosin (B1, B2, B3) | Fusarium verticillioides | Corn | < 25 °C 20% moisture content | Drought during the growing season followed by cool and wet conditions |

Let’s talk AFM1

At least 100 countries have some kind of legislation addressing the control of mycotoxins in feed and food. In fact, 66 have specific legislation concerning AFM1 in milk. Most countries measure using either the maximum level of AFM1 in milk in parts per trillion (ppt) or parts per billion (ppb). In the USA and most of Latin America the standard is 500 ppt while in Europe the limit would be 0.05 ppb; anything over 500 ppt/0.05 ppb is dumped.

Among all mycotoxins, aflatoxins are mainly a concern for the dairy industry. Aflatoxins are the metabolites produced by the mold species Aspergillus flavus and Aspergillus parasiticus. The four most common aflatoxins are B1, B2, G1, and G2 (Negash, 2018). In animals, their effects vary with the dose, length of exposure, species, breed, diet, or nutritional status. For example, in cattle, aflatoxin can cause reduced feed consumption, liver damage, cancer, a drop in milk production, immune suppression, and retarded growth and development (Negash, 2018).

When ruminants eat feedstuffs contaminated with aflatoxin B1 (AFB1) they metabolize it into aflatoxin M1 (AFM1), and unfortunately, this toxin can be excreted into the milk. To prevent animal toxicity and control AFM1 in milk, it is necessary to reduce AFB1 contamination of dairy feed by both preventing mold growth and AFB1 formation. Even with preventative treatment and management, the risk of feed contamination remains high. Therefore, the most convenient and cost-effective way to reduce the risk of mycotoxins is with the use of mycotoxin binders. Binders help to gather and adsorb mycotoxins in the gastrointestinal tract of the animal, once bound, the mycotoxins are eliminated through the feces.

Scientifically reducing the risk

Not all mycotoxin binders are equally effective, therefore, the effectiveness of any adsorbent to prevent mycotoxicosis has to be tested both in vitro and in vivo. The Agrimprove toxin solutions line has proven binding efficacy of aflatoxins based on in vivo scientific trials that demonstrate that the product can support performance and decrease the level of AFM1 in milk.

In an experiment at the Federal University of Santa Maria, 24 lactating Holstein dairy cows were equally divided over 4 treatments. The treatments entailed:

- A negative control group

- Aflatoxin free feed + Vitafix® 50 g/h/d

- Aflatoxin free feed + 500 ppb aflatoxin

- Aflatoxin free feed + 500 ppb aflatoxin + Vitafix 50 g/h/d

Experimental contamination consisted of a mixture of aflatoxins tested and shown to contain 93.8% AFB1. Diets were consumed for five consecutive days and the presence of AFM1 in the milk was analyzed on days 0, 1, 3, and 5 during the experiment.

Table 2: Efficacy of Vitafix in reducing aflatoxin M1 in milk over 5 days

| Treatment | Day 0 (ppb)* | Day 1 (ppb) | Day 3 (ppb) | Day 5 (ppb) |

| Negative control | 0.008 | 0.03b | 0.04c | 0.04c |

| Vitafix® | 0.004 | 0.02b | 0.02c | 0.01c |

| 500 ppb Aflatoxin | 0.009 | 1.28a | 2.03a | 3.18a |

| 500 ppb Aflatoxin + Vitafix® | 0.008 | 0.49ab | 1.02b | 0.91b |

As can be observed in the table, when cows were exposed to high levels of aflatoxin B1 contamination, a dose of Vitafix® significantly reduced the presence of AFM1 in the milk on days 3 and 5. After 5 days, the use of Vitafix® in the feed helped to reduce the presence of AFM1 in the milk by 71% compared to the challenged group with no toxin binder.

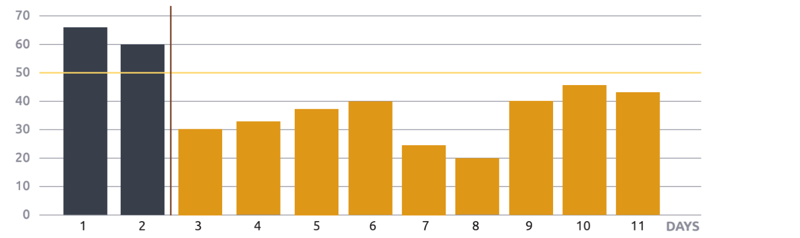

In another trial, on a commercial dairy farm in Parma, Italy, 800 lactating dairy cows were producing milk with levels of AFM1 above 0.05 ppb, the maximum accepted by the EU legislation. In response, Vitafix® was added to the ration at a rate of 50 g/h/d for 10 consecutive days. The AFM1 levels of the milk were then measured daily. In this case, the addition of Vitafix® resulted in a marked reduction of AFM1 in milk and helped the farm achieve levels within the established EU legislation in just 24 hours (Figure 3).

Aflatoxin M1 levels in milk after the inclusion of Vitafix

> horizontal yellow line = The maximum level of AFM1 allowed in EU milk

> vertical brown line = The day Vitafix®was added in the diet

Mycotoxins are naturally occurring toxic metabolites posing high risks to both human and animal health. In addition, they can heavily impact performance and lead to economic losses in wasted feed and lost production. Despite progress in diagnostic tools and solutions, full prevention of mycotoxins is complicated. Continuous awareness and a complete view of the agri-food chain are required to manage the risk of mycotoxins, safeguarding both feed and food safety.