In a diverse and continuously growing global poultry consumer market, it is of utmost importance to produce and supply the right quality poultry meat and eggs. This quality can be determined by various criteria (Figure 1) such as food safety, the way the poultry is raised (concept growing), meat characteristics (taste, smell, appearance, tenderness, size), and the convenience to prepare the food. The perception of quality can differ from region to region and from one culture to another.

Poultry meat processing plays a key role in the final food quality and cost, but previous activities also have a responsibility in this. It goes without saying that processing is a very precise and capital-intensive business, one where inefficiency and waste during the process are not tolerated. Today, state-of-the-art, highly automated, and transparent processing plants are able to produce any type of cut and deboned meat in the most efficient way. However, a lack of quality broilers and poor uniformity directly lead to more rejections, condemnations, second-grade quality meat, and inefficiency during the processing activity.

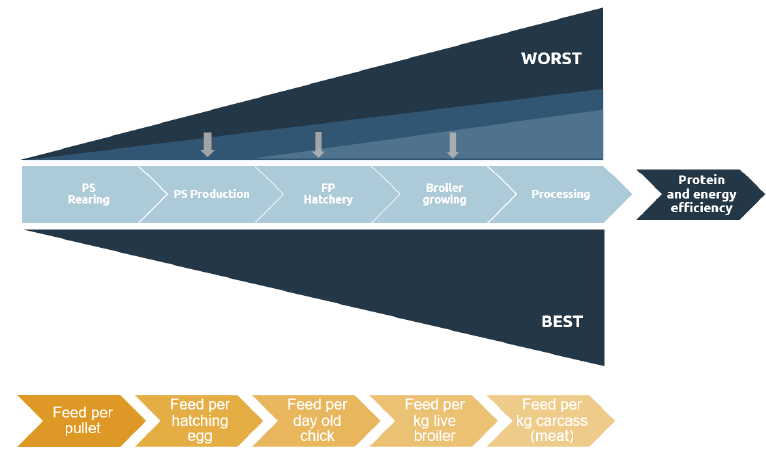

Feed cost, the most important production cost factor, is often the focus of the different stakeholders present in the broiler meat supply chain. Of course, each stakeholder has its specific Key Performance Indicator (KPI). Looking at a complete broiler supply chain, the differences (and variations) in feed cost efficiency will increase as you go further to the end of the chain (Figure 2). Therefore, at any stage, it should be the objective of any stakeholder or farm manager to raise and grow breeders and broilers with minimum variation within and between their flocks. If achieved, this will contribute to the zero-waste strategy of the processing plant.

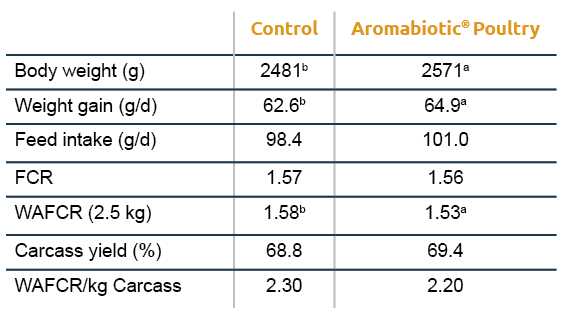

Medium-chain fatty Acids (MCFAs) are known for their antibacterial, antiviral, and immune-modulating properties. These properties mean they have great potential to improve both the food quality and performance of processing plants (Table 1). During the growing process of the broiler, the quantity and quality of the carcass are strongly dependent on protein efficiency. At that stage, the quality of the broiler (weight, uniformity, body composition, health status, bacterial contamination, etc.) and the environmental conditions will positively or negatively affect the quality of the carcass and the profitability of the processor.

Footpad lesions are a vital welfare parameter, while breast meat yield is an important indicator of the general health status of the broilers. Attention to these KPIs is an important indicator for broiler farmers looking to improve their growth process.

Field observations show that rejections, condemnations, and downgraded meat and cuts can reach up to 5%. In most cases, the cause for downgrading is due to multiple causes and is very often linked to the quality of the day-old chick, mycotoxins, diseases (E. Coli), nutritional and digestive problems, climate control, general farm management, as well as rough handling during catching and transport.

MCFAs have several positive effects on broiler breeders. Not only will MCFAs support genetic progress, as well as more uniform and vital day-old chicks, but they also have positive effects during the growth process to positively impact protein deposition (Figure 3), protein quality, and protein efficiency. Overall, MCFAs can contribute to poultry health, reducing downgrades and increasing the profitability of the processing plant.