Precision livestock farming is a rapidly emerging trend in animal agriculture. It uses technology and artificial intelligence to monitor and manage animal health and performance, thereby increasing efficiency and profitability in the production chain. Recently, the Global Poultry Category Manager for Agrimprove explored the concept of precision livestock farming, its applications, and the impact it can have on the poultry production chain at an IPPE 2023 TechTalk.

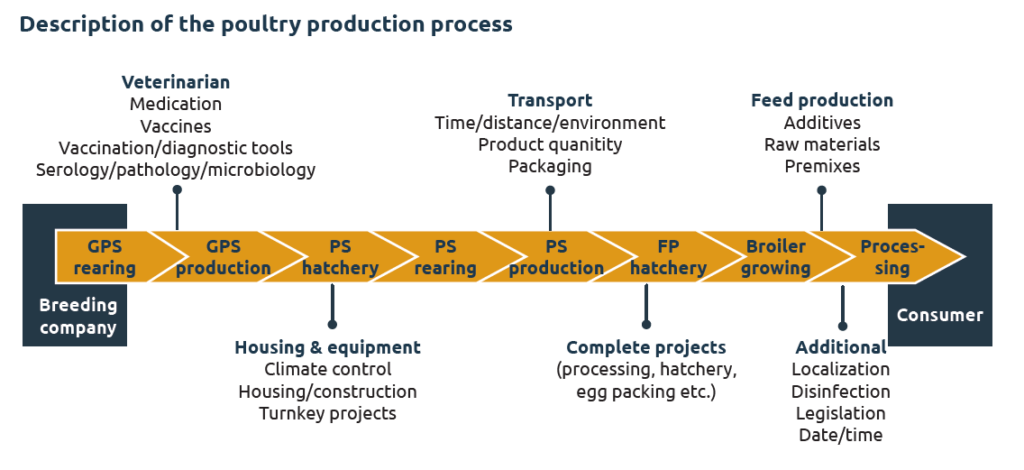

The poultry production chain is a complex network of activities involved in producing broiler meat for consumers. The activities of these different stakeholders—breeders, hatcheries, feed manufacturers, veterinarians, transporters, and processing plants—impact the final product quantity and quality. Precision livestock farming aims to optimize this production chain by using data and technology to monitor and manage animal health and performance and thereby optimize efficiency, reduce waste, and provide a consistent and healthy final product to the consumer.

Simplifying a big concept

Precision livestock farming involves the collection of data through various sources, such as animal sensors, cameras, and data logs. This data is then analyzed using machine learning and artificial intelligence algorithms to provide insights into animal health and performance. The data can also be used to monitor environmental conditions such as temperature, humidity, and air quality, which can affect animal health and productivity.

Additionally, in the future, other areas of poultry meat production can be included with the data collected from precision farming to form a blockchain (Figure 1). By using blockchain, all parties involved in the poultry production chain—from the breeding facility to the processing plant—can have access to a shared ledger that records information about the product at each stage of production.

Description of the poultry production process

This allows for greater accountability and trust between different players in the supply chain. For example, consumers can track the origin and journey of their poultry products, ensuring that they are buying safe and ethically sourced food. With the use of blockchain, the food industry can move towards a more transparent and efficient system that benefits all parties involved.

Accuracy is not a setting

The production of bolts and broilers has vastly different processes and requirements. While the manufacturing of bolts heavily relies on accurate settings and machinery, broiler production—due to the nature of living organisms—requires accurate predictions to optimize the health and growth of the flock. Accurate predictions allow producers to anticipate changes in bird growth rates, detect potential health issues, and optimize feed formulations. Therefore, compiling the right data and effectively communicating it is key to future broiler production.

In the past, data collection on poultry operations was mainly done through manual methods such as paper-based records and visual inspections. However, with the advent of new technology, data collection methods have evolved to include sensors, automated equipment, and computerized data management systems. These new methods allow for real-time monitoring of the birds’ health, environmental conditions, feed consumption, and other important metrics.

Accurate data input and analysis can help producers identify trends in bird behavior and growth rates, predict potential health issues, and optimize feed formulations. However, this data must be interpreted and acted upon by skilled personnel who have a deep understanding of avian biology and behavior. Ultimately, the production of broilers will always require a blend of scientific knowledge and practical experience to ensure optimal conditions for the birds. While precision farming techniques can provide valuable data and insights, they cannot replace the importance of skilled management and care.

Utilizing the data

Precision poultry farming will revolutionize the way broilers are produced. But with so much data available, producers will face the challenge of how to properly utilize it. While collecting data on bird behavior, feed intake, and environmental conditions can help optimize flock growth and health, interpreting and communicating these findings remains a significant challenge. Data collection is the easy part of precision poultry farming, interpreting and communicating its findings is the challenge we currently face.

For example, a producer may have data showing the birds are not eating enough feed. However, this could be due to a number of factors such as a problem with the feed itself, a change in the environment, or a health issue. This data needs to be properly analyzed and communicated so that appropriate changes can be made. With so many interconnected pieces of data forming a web, it is important that all parties involved in the poultry production chain have access to the same information and are communicating effectively.

Benefits of the future

A challenge to precision poultry farming is human resistance to change. Operations may be hesitant to adopt new technologies or methods, especially if they have been successful in the past. However, in order to stay competitive and meet consumer demands, it is essential to adapt to new practices. Precision farming requires a shift in mindset and a willingness to embrace new technologies and methods in order to maximize the benefits of this approach.

Precision livestock farming is a powerful tool for improving efficiency and profitability in the poultry production chain. By monitoring animal health and performance, producers can identify potential issues and take corrective action before they become major problems. Additionally, precision livestock farming is able to improve data transparency and traceability throughout the production chain. By collecting and sharing data among stakeholders, producers can better understand the factors that affect animal health and performance. This can lead to better collaboration and communication between all stakeholders in the poultry production chain, which can improve overall efficiency and profitability. As data collection methods continue to evolve, the poultry production chain will become even more efficient and sustainable, benefiting everyone involved.