With changing breeding programs and broiler breeds becoming more resilient, and with new techniques and new insights in the functioning of the GIT of broilers, new approaches can be applied in order to optimize the protein production. Not only a preventive strategy to minimize the risk on bacterial problems, either caused by nutritional disbalances or by direct contamination, but also a more active strategy can be used in order to fully utilize the potential of the GIT.

Broiler performance is depending on many different factors. Most of them differ substantially depending on the region, such as climate, altitude, stocking density, raw materials, disease pressure, natural light cycle,… . Others can be the same in all countries: breed, equipment,… . But in fact each flock will be specific as each egg can only be hatched once and day old chick quality (size, immune status,…) and flock quality will therefore be different.

It is the objective of the broiler manager to manage and grow the broilers according to the need of the processing plant or according to the need of the live broiler customer. And this in an efficient and economical way respecting the wellbeing of the animals as well as the environment.

As feed cost is responsible for up to 70 % of total production cost for broilers, feed efficiency is extremely important. For exemple, an improvement of 2% in feed conversion ratio (FCR) can result in a reduction of 1 to 1,4% of the total production cost. In broiler production an improvement of FCR does not automatically imply that a reduction in feed consumption should be the objective. It is generally well known that if, given a certain feed formulation, feed intake is too low FCR will increase. On the other hand when feed intake is too high, for instance because passage rate is too fast, FCR will also increase. This means that there is an optimum feed intake in relation to the development, quality and activity of the intestinal tract.

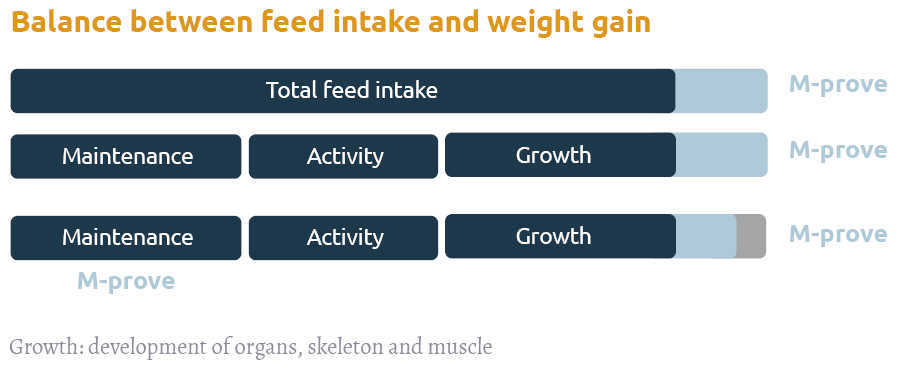

In broiler production, the balance between feed allocation for weight gain and feed allocation for maintenance is essential to costing and hence should be focused at (figure 1).

Looking to the genetic development over the last decades, progress in weight gain and FCR have been made in combination with increasing daily feed intake and by improving the efficiency of protein deposition. This genetic progress in weight gain also goes in line with changes in organ and skeleton development as well as an increased need for water and nutrient supply, and an increased detoxification capacity and increased oxygen need (figure 2).

It is known that a positive relation exists between the development of the small intestine and feed intake. Focusing on the development and quality of the small intestine is key to optimize the intestinal performance.

M-prove, a product based on a specific combination of Medium Chain Fatty Acids (MCFAs) and phytogenic components, was developed to increase the activity of the intestinal tract, to stimulate feed intake to rebalance the ingested nutrients in favor of weight gain by reducing the need for maintenance.

A trial in China in collaboration with an independent research facility has indicated that M-prove leads to an increased pancreas size, a more optimal development of the small intestine (size and density) and a higher acidifying capacity of the gizzard. These parameters are very indicative for the digestive and absorptive capacity of the GIT (table 1). In another trial, M-prove was shown to stimulate the secretion of digestive enzymes in both the pancreas (such as amylase, trypsin and pepsin) as well as in the small intestine, indicating that both starch and protein will be better digested (table 2).

Stimulating GIT development, integrity and its activity,results in an increased feed intake and an increased protein deposition. On average, improvements of 1 to 2 grams extra feed intake/day – and even higher improvements of daily weight gain – are commonly observed in the field (table 3). This – together with an increased percentage in liveability – contributes to a better gross margin/m².