Every day, somewhere in the world, we are faced with climate change: heavy rains, ultra-high temperatures, drought, strong winds, melting glaciers, … and all of these natural events challenge food safety and food security. At the same time, we observe that the world population continues to grow – and the need for animal protein, especially poultry protein, is increasing. These two factors are making animal protein production more challenging. Not only in terms of protein efficiency, but also in terms of costs and of sustainability in general.

Extreme climate circumstances result in cereals of variable quality and yield. Variability in nutritional value, as well as variability with regard to food safety due to fungi contamination and their metabolites. Poultry producers and poultry nutritionists will need to adopt technology and science to cope with these variabilities in order to ensure that the end product they produce remains safe and of a consistent quality.

Variability: a challenge to meet – not a problem to be solved

The more variability there is in raw materials the more intensive monitoring programs need to be applied to adjust the nutritional values to prevent big fluctuations in animal performance. With regard to the variability of nutritional value, one can say that, within certain constraints, the effects (either positive or negative) are linear and are generally known – and so, it is easier to calculate the dosage that is needed to equalize this variability. Food safety is much more complex – but, at the same time, much simpler: either the food is safe, or it is not safe. Concerning food safety, we generally talk about quantifying the risk and estimating the probability of food becoming unsafe; whereas, with nutritional values, we tend to take probability studies less into account.

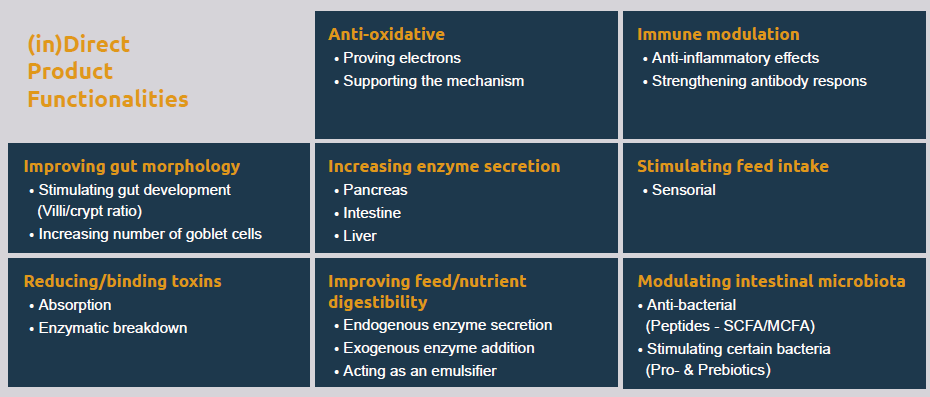

Variability as a result of environmental circumstances between, but also within, flocks always affects profitability – if not with the broiler grower or on the breeder farm, then in the processing plant. In a production process, flock uniformity is key to optimizing yields. To reduce the risk of food unsafety, and to reduce the negative impact of nutrient variability on performance, certain functionalities are needed. Figure 1 summarizes the main functionalities provided by alternative feed additives in order to ensure safe and efficient poultry production.

Feed additives for poultry that reduce variability

Variability is a challenge, but it should not be a problem. When variability is managed properly, the risk of problems is greatly reduced. For example, in a broiler flock, the maternal antibody titers against infectious bursal disease (IBD) at point of hatch vary among the individual day-old chicks. This variability determines how often and when this flock needs to be vaccinated in order to reduce the risk of IBD infections. Improving uniformity of maternal immunity, and improving the response to vaccinations, reduces the variability in individual sensitivity to IBD infection pressure.

Feed additives play an important role in reducing this variability between and within flocks and in reducing the risks to food safety, whether they are toxin-related or bacteria-related. Additives should have 1 objective in the end feed, and that is: to improve the efficiency of producing edible poultry protein in a sustainable way. It is senseless to improve the efficacy of production but still have a high risk to food safety or animal health or to destroy the surrounding environment. Food safety should be one of the main aspects of sustainable agricultural production. If the food is not safe, all of the resources used to produce it have been wasted. The same is true with regard to animal health. If the animal contracts IBD or any other disease causing a high mortality rate a few days before being slaughtered, all of the resources used have been wasted as well.

Royal Agrifirm group has developed a strong poultry product portfolio, based on several functionalities and focusing on 3 main principles: efficiency, food quality, and respect for animals, climate and environment (Figure 1). All of the products in the poultry product portfolio contain elements of these principles – some are found in equal proportions, and others focus more on one or two principles and less on the third. For instance, our 2 mycotoxin binder product ranges (Myco-AD and Vitafix) are well appreciated by the poultry industry, as they contribute significantly to eliminating mycotoxins from the intestinal tract. Therefore, they safeguard not only meat or eggs from becoming contaminated but they also ensure intestinal gut integrity whereby performance can be maintained. So, we focus mainly on food safety with these product ranges, but we don’t neglect the effect on protein efficiency and animal welfare.

Our newly developed product, S-prove – created to prevent Salmonella colonization in the intestine and thus reduce the risk of Salmonella-positive meat – is a good example of how additives can contribute to improving sustainability in poultry production. The product stimulates the animal’s resistance to Salmonella infections and strengthens the response to vaccinations, thus increasing the protective effect against viral and bacterial challenges. Here as well, the 3 main principles are represented in the product. The same is true for C-prove 80 – a product being added to the drinking water in the beginning of the growing period and during critical periods, with the objective of improving antibody response and increasing the animal’s resilience.

Variability in the nutritional value of raw materials would be the second topic to work on. This for 2 reasons: a) because it will result in increased variability of the end product, which is meat or eggs; and b) as continuous changes in nutrient supply affect the microbiome composition which can affect efficiency, but also in the worst-case scenario this affects animal health and animal welfare. Variability in the nutritional value of raw materials is mainly related to efficiency. It goes without saying that protein efficiency depends on the digestibility of the feed, the absorption of the nutrients, and then on directing the nutrients into growth. Both exogenous and endogenous enzyme secretion are important in this. In young animals, in particular, additional exogenous enzymes are needed to increase the nutrient value of the raw materials/feed, which contributes not only to reduced cost but also to reduced usage of arable land – especially for those cereals or oil grains which have a higher carbon footprint. As with food safety, one can increase the animal’s potential to become more sustainable by stimulating the animal to secrete more endogenous enzymes itself, which improves both carbohydrate and protein digestibility, as well as enzymes that reduce the effect of oxidative processes that damage cells and reduce the capacity to perform well. M-prove, a product developed to improve broiler performance, contains these functionalities and stimulates the secretion of digestive enzymes in the intestine and pancreas as well as the secretion of anti-oxidative enzymes in the liver. Thanks to this characteristic, M-prove can be used under many different environmental circumstances.

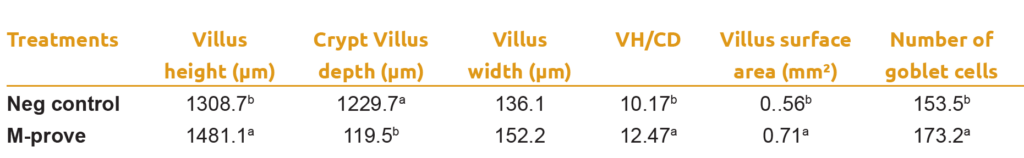

Intestinal homeostasis is fundamental to good performance – but it also respects the well-being of the animal, the environment and the climate, and it contributes to supporting food safety. The gastrointestinal tract is the largest organ present in broilers, and it requires lots of energy and proteins to develop, grow and be active. Research data on M-prove have shown that the gastrointestinal tract quality and activity can indeed be influenced from the beginning to the end, improving not only gut morphology but also cecal microbiome and volatile fatty acid production, which increases the net energy available for growth and improves water and mineral re-absorption in the ceca which reduces the risk of wet litter.

Table 1: The effect of M-prove on gut morphology and on gut activity | a,b significant different at P<0,05

Conclusion

Poultry is fed and produced all over the world under different conditions with different raw materials, and it is subjected to a wide range of stressors that create increased risks to food safety and increased variability in performance between and within flocks. At the same time, consumers are demanding more standardized and safer poultry meat. Feed additives that possess the proper functionalities can contribute significantly to reducing the variability, and hence the waste, in the production process – and thus, they contribute significantly to improving sustainability. In this way, feed additives for poultry contribute to the consumers’ need for safe and sustainable poultry proteins.